SAMPLE AND MANUFACTURING

Connecting fashion brands with manufacturers

Manufacturers that are ethically operated and conscious of environmental impact

Sample and Manufacturing

Haysal connects fashion brands to Manufacturers that respect workers’ rights and pay decent salaries which means: no child labour, no forced labour, safe & healthy working conditions, reasonable working hours, no union, ethical manufacturing!

We believe in full transparency in the sample and production process in order to ensure the product is ethically produced, therefore, our Clients have full access to the manufacturer that they are working with.

A large part of sustainable production is in the materials that Clients choose to work with. With increased demand and our extensive global network of suppliers and fabrics mills, we are able to provide a wide variety of sustainable options for our Clients.

With the support of Haysal’s long-term relationships with the Manufacturers, and with the help of our streamlined systems, our Clients have the opportunity to move through the typically risky and complex development and production process knowing we have their back to meet all production goals.

Haute cotoure

Eastern and western pret wear

Modest wear

Bridal wear

Ready to wear

Formal wear

Kids wear

Active wear

Sports wear

Loungewear

Swimwear

Surf

Ethical & sustainable manufacturing

Haysal carefully monitors that the manufacturers we connect our clients with are ethically operated and conscious of environmental impact.

REGULATIONS AND CERTIFICATIONS MAY INCLUDE:

- Training workers in environment protection

- Plastic-free options for all packaging & trims

- Ecological waste management systems and environmental protection policy

- Water, noise and air emission consumption regulations

- Registration with local environment department for the environmental impact of its business activity

- Sustainable natural or recycled material along with ECO-friendly dyes used

ETHICALLY OPERATED CERTIFICATIONS MAY INCLUDE

- BSCI certification

- SA800 certification

- SMETA certification

- GOTS certification

Quality

The quality of your garment is vital in order for your fashion label to ensure it is sustainable and holds its value. We want to help our clients create quality pieces that last. Our team assist in this by creating checkpoints to ensure the proper testing is done prior to bulk production being sent, as well as in the sample process.

- Assistance with designing to a feasible production plan.

- Extensive fabric sourcing & selection.

- Detailed tech packs.

- In-depth sample reports.

- 3rd party QC.

- Factory transparency.

- Connecting you with factories that utilise both revolutionary machinery as well as handmade intricacies when required.

- Connecting you with factories that are professional & experienced in the product type you are creating.

Why produce in Bali?

- MOQs of 50 pieces per style per colourway (cost-reflective)

- Wide variety of sustainable fabrics

- Lenzing fabrics

- Manual print and dying options for low quantities

- Quality product

- Lifestyle

- Slow Fashion

Why produce in China?

- MOQs of 100 pieces per style per colourway (cost-reflective)

- Wide variety of sustainable fabrics

- Efficient turnaround times

- Efficient communication

- Certified factories

- Quality product

- Competitive pricing

- No import duties to Australia

Why produce in India?

- MOQs of 50 pieces per style per colourway (cost-reflective)

- Wide variety of sustainable fabrics

- Organic fabrics

- GOTS Certified factories

- Manual prints and dying options

- Quality product

- Slow fashion

- Competitive pricing

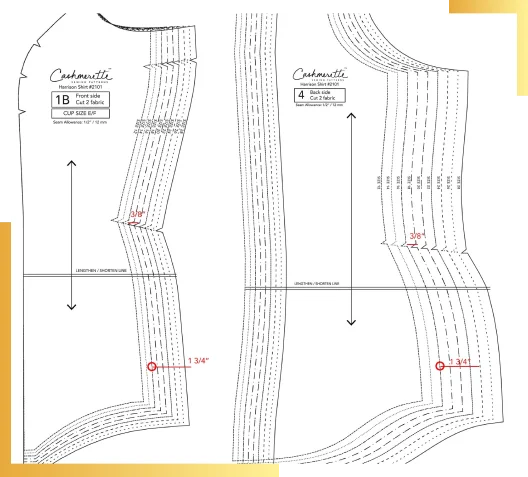

Grading

The majority of manufactures will grade your garment with a 50mm grade, however if you would like to custom grade your designs then you will have to work with a designer to have your patterns graded as requested.